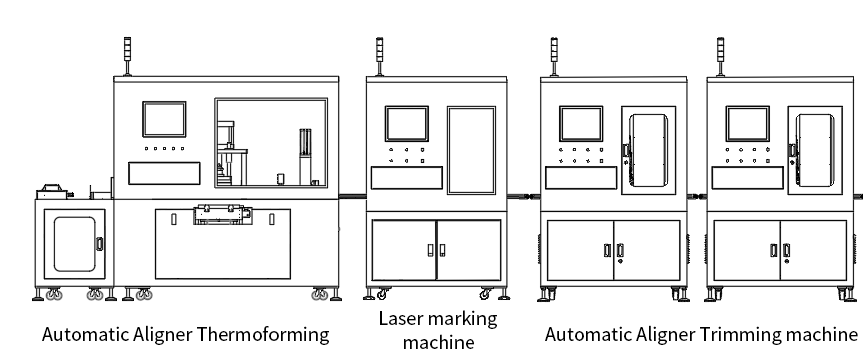

Umugqa wokukhiqiza we-Prismlab othomathikhiyakhelwe ukuthi isetshenziswe ekucubunguleni nasekukhiqizeni ama-aligner acacile.Okukwazi ukubona ukwakhiwa kwe-aligner ecacile ku-thermoforming, ukumaka nge-laser nokusikwa ngokuzenzakalela, konke ukusebenza kahle kuzothuthukiswa kakhulu ekukhiqizeni ngobuningi.

2. Ipharamitha ye-Equipment Technique

2.1 Umdwebo Osebenzayo Womugqa Wokukhiqiza

| Cha | Igama Lomkhiqizo | Ubukhulu | Isisindo | Amandla | Amandla kagesi |

| 1 | I-Automatic Aligner Thermoforming | 2.7*1.1*2 m | 800KG | 3.5KW | 220 V |

| 2 | Umshini wokumaka we-laser | 1.4*1.1*2 m | 400 KG | 2.5KW | 220 v |

| 3 | Automatic Aligner Ukunquma umshini | 1.3*1.1*2 m | 600KG | 3.5kw | 220 v |

| / | / | / | / | / | / |

3.Amapharamitha obuchwepheshe omshini wokugcwalisa i-Thermoforming ozenzakalelayo

1) Ububanzi bokushisa obumbayo obulawulekayo: 150 ℃ -400 ℃s, ucwecwe lwalushisiswe ngokulinganayo

I-2) Ukusebenza kahle kokushisa: 3) Ibanga lengcindezi yokwakha elilawulekayo: Ibha ye-1-10

4) Ukusebenza kahle kokwenza (isikhathi esisodwa sokuqeda ukwakha): ≤15 imizuzwana

5) Kuhle kakhulu ekuhlanganiseni

6) Izinga elingalungile lokwakheka (izinga lokuphinda lisebenze) : <1%

7) Ngomsebenzi wokuhlonza umlingisi oyimodeli

I-4.Imingcele yezobuchwepheshe esebenzayo

1) Izinga lokuqashelwa okubonakalayo > 99%

2) Isikhathi sokuqaphela okubonakalayo ≤0.2 imizuzwana

3) Izinga lokuqashelwa kokumaka ikhodi ye-QR ye-laser > 99.9%

4) Isikhathi sokubhala ikhodi esisodwa se-Laser < 2 imizuzwana

5) Izinga elingalungile lekhodi ye-laser lisondele ku-0

5.Amapharamitha obuchwepheshe omshini wokusika we-Automatic Aligner

1) Unqenqema lokuqondanisa okucacile ngemva kokusikwa luhambisana nomugqa wokusika wangempela, futhi ukunemba kungu-<0.3mm

2) Isikhathi sokusebenza sokunquma ukulinganisa okukodwa okucacile: 3) Akukho ukuphazamiseka enqubweni yokusika

4) Ngemuva kokusikwa, izinga le-edge burr lokuqondanisa okucacile lingaphansi kuka-2%

5) Izinga lokusika elibi (rework): <1%

6) Nikeza amathuluzi asekelayo kanye nesofthiwe yokuxazulula isizukulwane esizenzakalelayo semigqa yokunquma kanye nemisebenzi yokulungisa ngesandla;

7) Nikeza ngamathuluzi asekelayo kanye nesoftware yokuxazulula umsebenzi wokwenziwa komumo wesisekelo wokunquma nokubeka;

8) Nikeza isikhombimsebenzisi se-API, xazulula indlela yomugqa wokunquma ngokwezifiso, umsebenzi wokusetha we-Angle wamathuluzi;

Isikhathi sokuthumela: Oct-10-2022